Food safety failures cost millions and destroy trust. DIRATECH empowers food manufacturers and machine builders with next-generation X-Ray inspection that detects what others miss — protecting consumers, brands, and bottom lines.

About us

DIRATECH is built by a team with a recognized track record and industry-leading innovations in X-Ray solutions and technology.

Our mission: help industries detect more, recall less, and future-proof their quality control.

We believe in long-term partnerships with both food manufacturers and machine builders (OEMs) to create value beyond hardware.

Contact usTraditional X-Ray misses 40–70% of these contaminants. DIRATECH detects them. Cuts false rejects by 30–50%, saving a significant amount annually in wasted products.

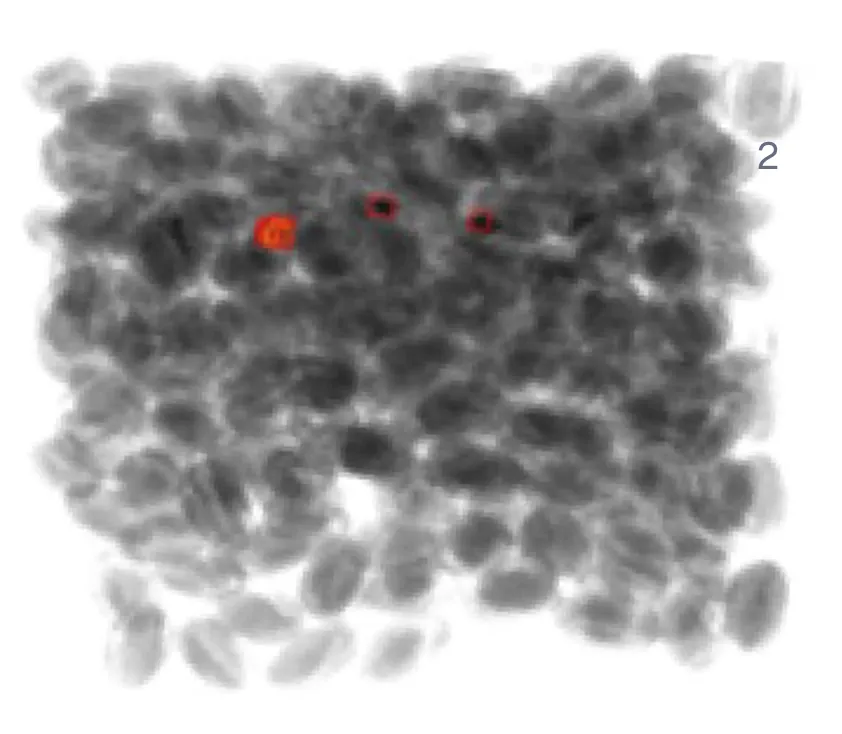

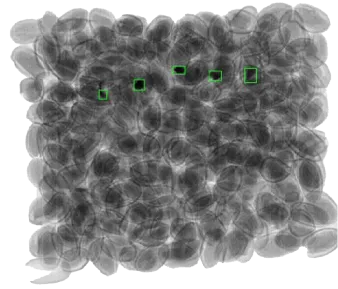

Dangerous Real World Contaminants in Complex Products (glass/stones)

Example: Pistachios bag

Top Market Manufacturer Detection Results

1 - 49%

1 - 60%

Our AI Powered Detection Results

1 - 86%

1 - 100%

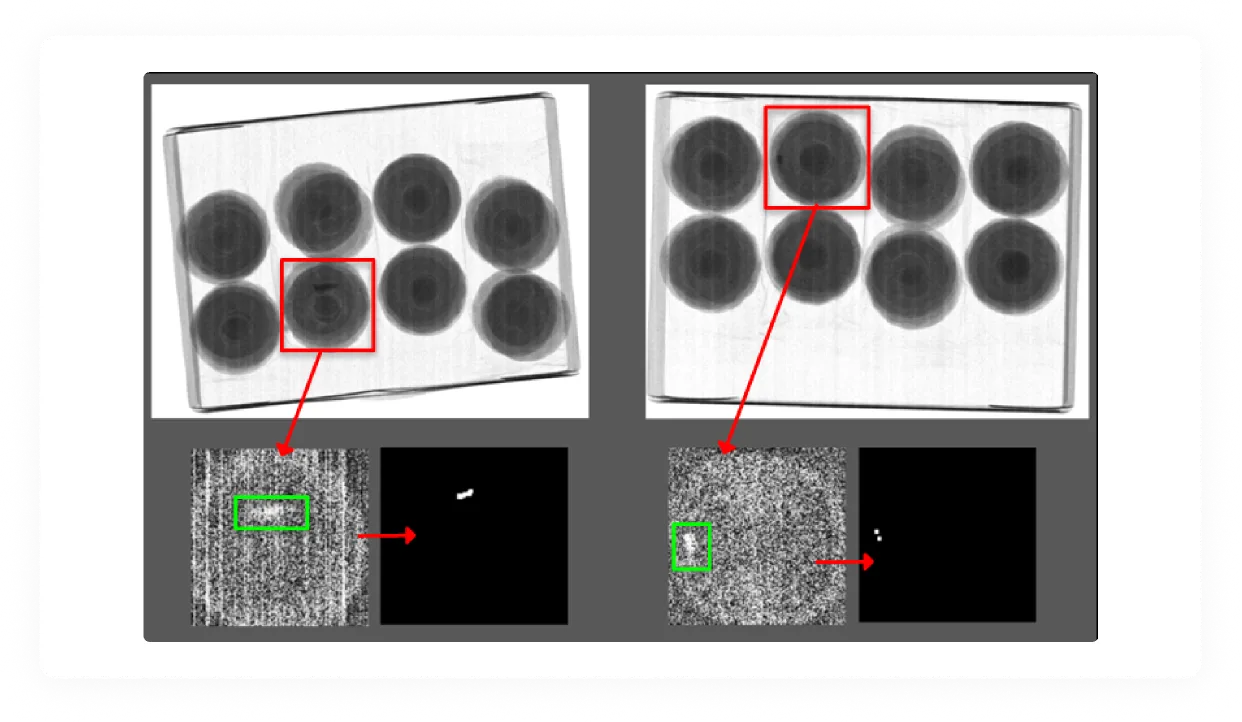

Lightweight Contaminants

Rubber from the Processing Machine

Example: Box of Biscuits

We Reveal Contaminants Which Are Not Detectable by Conventional X-Ray Machines!

DIRATECH combines X-Ray imaging, machine learning, and real-time cloud sync into one seamless process.

Affordable & Accessible

Our flexible pricing combines low entry costs with a subscription model tailored to your budget

More Accurate

Detection of hard-to spot challenging contaminants, fewer false positives, less waste

AI-Powered & Automated

Provides qualitative + quantitative insights (more than just "pass/fail"). Learns continuously from your line. Self-learning, minimal setup

Cloud-Connected

Real-time monitoring, compliance automation, instant HACCP & IFS reports

Energy-Efficient & Compact

2x reduced system energy, reduced operational costs

Ready to elevate your inspection?

Talk to our team and discover how DIRATECH can fit your production needs.

Contact usChoose what fits your needs — from turnkey systems to OEM software

AI Hybrid Engine – Advanced image processing + deep learning + material separation. Photon-Counting Detectors – Richer imaging, sharper contaminant detection.

Cognitive inspection

Outputs human-like interpretations, not just pass/fail.

Synthetic data generators

Rapid setup for new products without long learning curves.

Instant HACCP & IFS reports

Cloud real-time reporting and compliance.

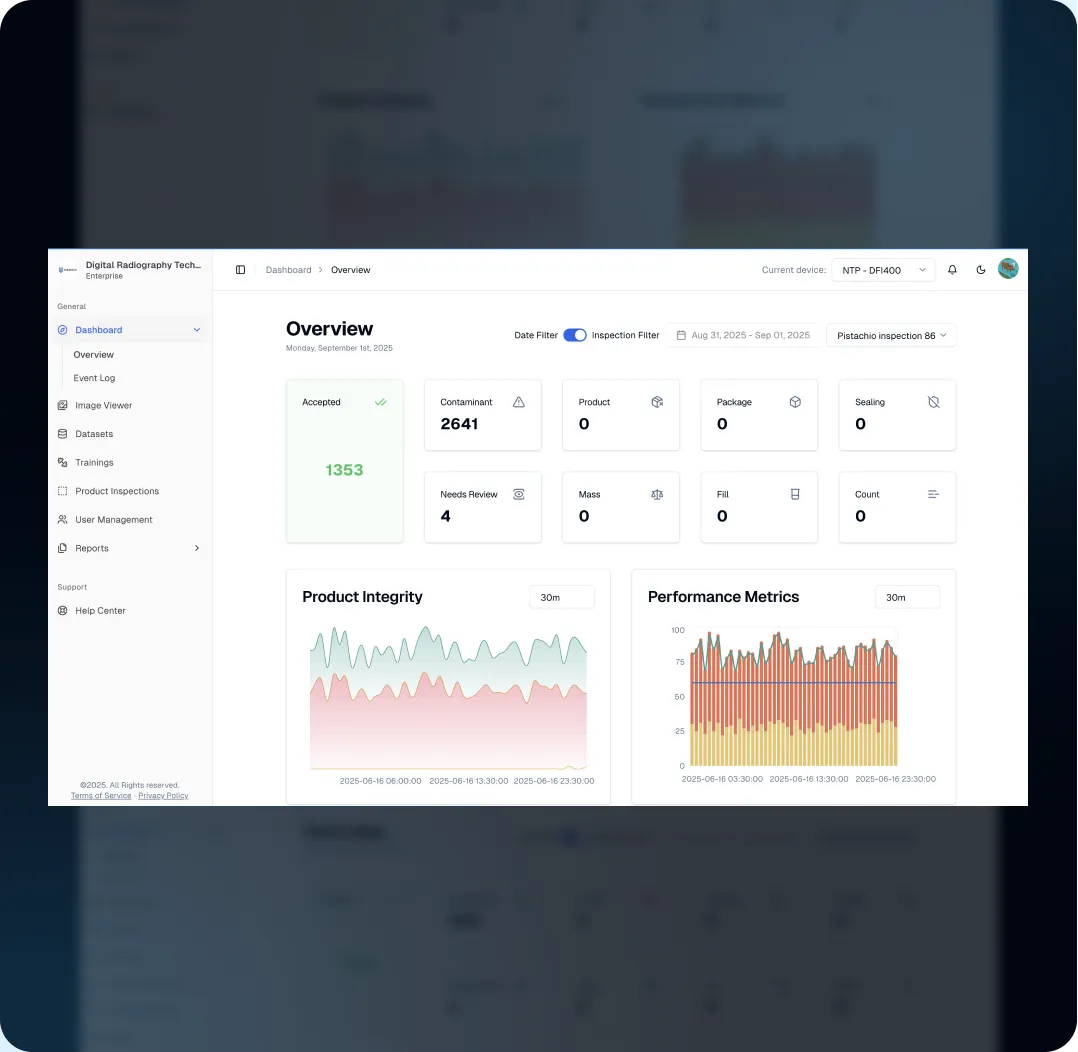

Manage users, review captured scans, and track system performance — all through a unified dashboard that works seamlessly across desktop and mobile.

Dashboard

Live access to inspection history, alerts, and system status — from anywhere.

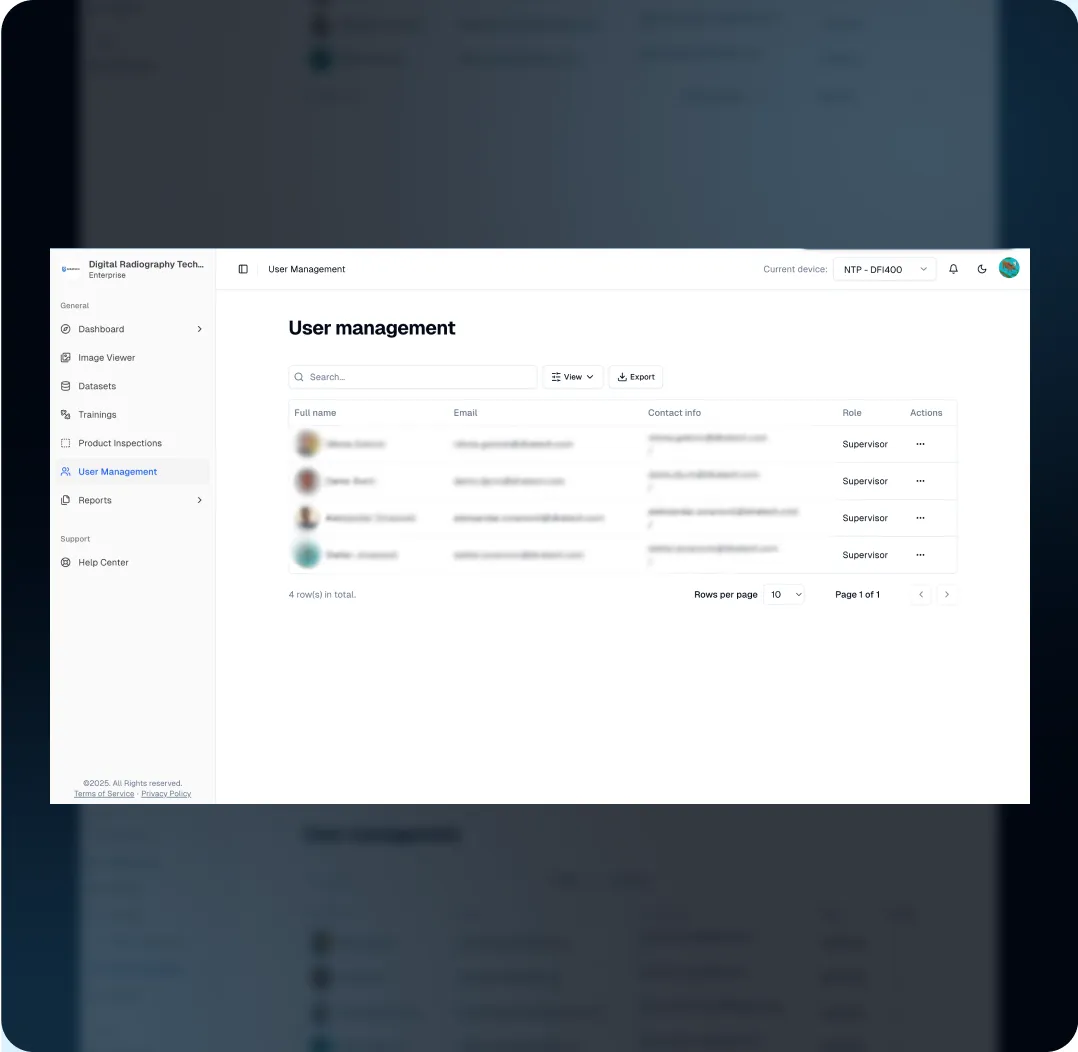

User Management

Add, remove, and manage operator access with role-based control.

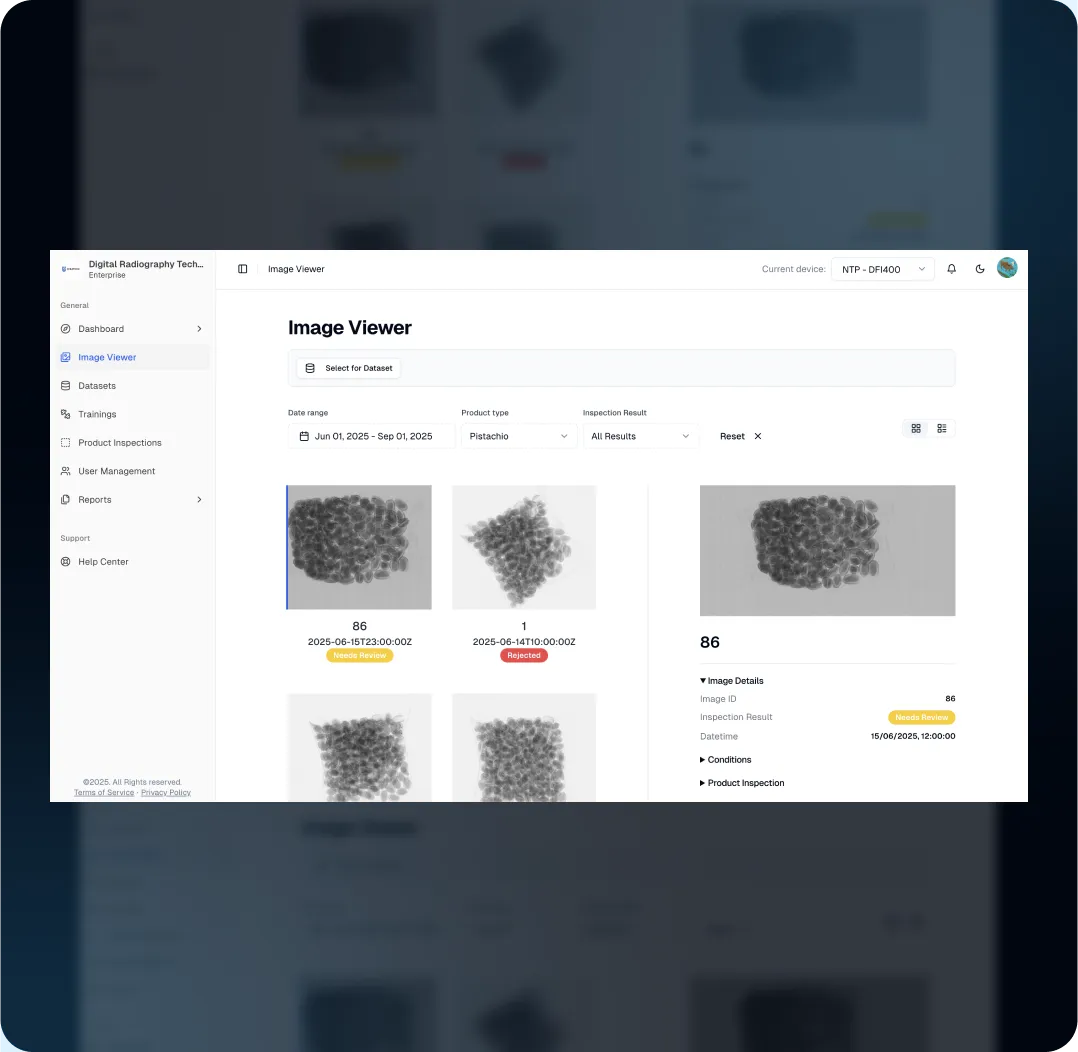

Image Viewer

Review detailed scan results and verify inspection accuracy with ease.

What industries is DIRATECH most suitable for?

What types of contaminants does the DIRATECH solution detect?

Do you detect other types of product anomalies besides contaminants?

Do you adapt systems to specific user needs?